After many success stories in the biggest infrastructure & transport projects in Turkey, Haulotte & Acarlar are adding another layer of success in the world’s biggest airport project in Istanbul by deploying the entire construction site with a large number of Haulotte innovative products.

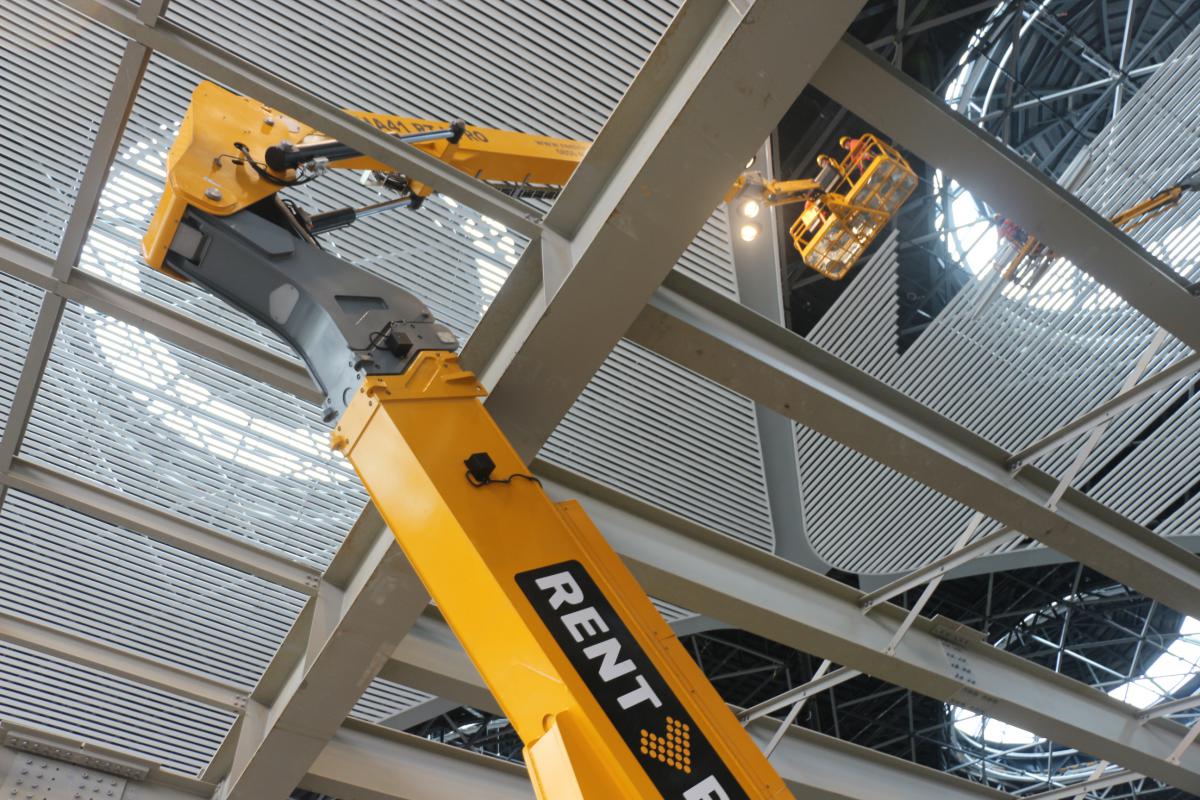

Boomlifts were ideal to reach the difficult working area

Another popular model is the new OPTIMUM 8, AC drive, which can work outdoors in winds up to 45 km/h while maintaining the load capacity of 230 kg.